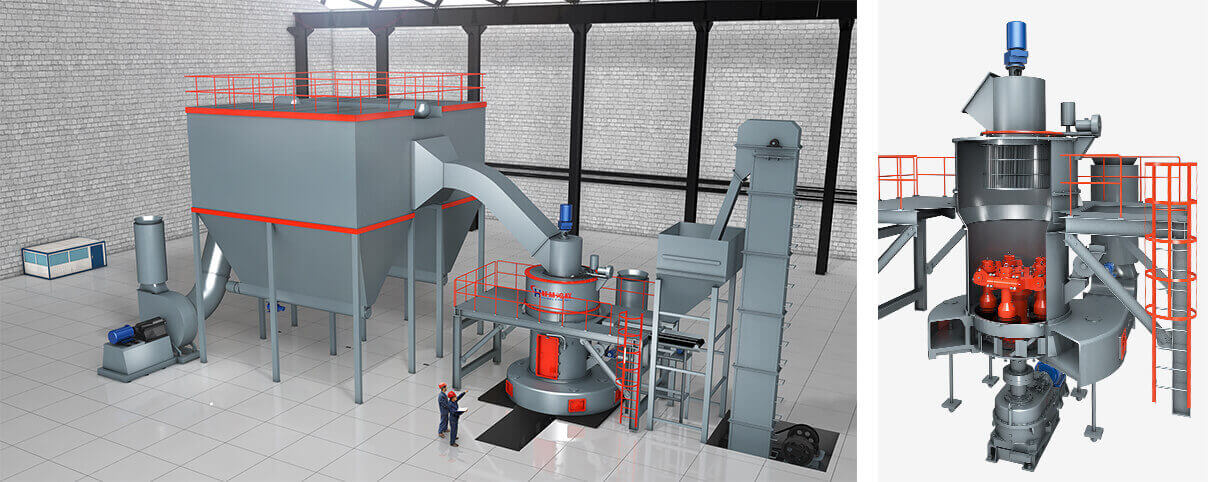

Solid and reliable integral base structure has strong shock resistance and can improve the stability and reliability during equipment operation.

understand

NEED A SOLUTION?For more grinding mill information or quotation request please contact with us.

Inquirycontact us

Welcome to Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Phone:86-0773-3568321

- Address:Yangtang Shanshui Industrial Park, Xicheng Economic Development Zone, Guilin City, Guangxi Province, China

- E-mail:hcmkt@hcmilling.com

© Copyright - 2010-2023 : All Rights Reserved. Hot Products - Sitemap - AMP Mobile

Mill Grinder, Ultra Fine Grinding Mill, Powder Paint Grinding Mill From China Supplier, Coal Grind, Ultra Fine Mill, Petroleum Coke Vertical Roller Mill,

Mill Grinder, Ultra Fine Grinding Mill, Powder Paint Grinding Mill From China Supplier, Coal Grind, Ultra Fine Mill, Petroleum Coke Vertical Roller Mill,